Bioreactor with Dual Functional Ceramic Membrane Used for Wa

| 论文类型 | 技术与工程 | 发表日期 | 2008-01-01 |

| 来源 | 第三届环境模拟与污染控制学术研讨会 | ||

| 作者 | Zhang,Yongminga,Chen,Suhuab,Wa | ||

| 关键词 | bioreactor, ceramic membrane, wastewater treatment, membrane foul | ||

| 摘要 | A new kind of bioreactor including a group of dual functional ceramic membranes was developed and used for wastewater treatment. The ceramic membranes could be used for aeration and filtration alternately, so fouling to ceramic membrane would be palliated | ||

Zhang, Yongminga; Chen, Suhuab; Wan, Shiguib

a. Department of Environmental Engineering, Shanghai Normal University, Shanghai, 200234, P. R. China, E-mail: zhym@shnu.edu.cn;

b. Department of Environmental and Chemical Engineering, Nanchang Institute of Aeronautical Technology, Nanchang, 330034, P. R. China

Abstract

A new kind of bioreactor including a group of dual functional ceramic membranes was developed and used for wastewater treatment. The ceramic membranes could be used for aeration and filtration alternately, so fouling to ceramic membrane would be palliated effectively as its dual functions. Switch interval, i.e. from filtration to aeration or aeration to filtration, was set in 10 minutes and flux of the membrane could be recovered properly at this frequency. The ceramic membranes with pore size of 15 mm were also effective to turbidity removal, and effluent turbidity was less than 1 NUT (Nephelometric Turbidity Unit), which equals natural gravity sedimentation of 12 to 36 hours. The treated wastewater penetrated through sludge bed formed on surface of the ceramic membranes according to the test. For 100 days operation, COD removal ratio was 88% ~ 97% for influent COD of 154 mg/L~1389 mg/L, and NH3-N removal ratio was 98% for influent NH3-N of 7.52 mg/L~51.35 mg/L. Some washing methods aiming at fouling ceramic membrane were discussed and compared each other, experimental results indicated that surface fouling is main factor and NaClO is better washing agent for flux recover.

Keywords: bioreactor, ceramic membrane, wastewater treatment, membrane foul

Introduction

Fouling control is a major problem in membrane bioreactors (MBR) used for wastewater treatment because present systems, in spite of having higher BOD (biological oxygen demand) and COD (chemical oxygen demand) removal (Beaubien et al, 1996; Trouve, et al, 1994) due to higher biomass concentration, are not economically competitive for this application (Owen et al., 1995). The membrane with dual functions i.e. alternate functions of system aerator and filter is one of potential and economical methods to prevent or avoid foul (Scott and Smith, 1997). In wastewater treatment by membrane bioreactor, continuous biological treatment is coupled to a membrane, which permeates treated liquor, but prevents biomass loss from the reactor. Using membrane filtration technology, the need for flocculation in conventional wastewater treatment processes can be removed and a highly active microbial population can be maintained regardless of its flocculating ability.

The MBR combines a membrane process for liquid-solid separation instead of the more usual gravity sedimentation (Trouve et al., 1994). Such a design leads to the treated water having very low turbidity and being free of bacteria (Chiemchaisri et al, 1994). The absolute retention of microorganisms facilitates an increase of sludge concentration, and furthermore, allows a complete separation of the hydraulic retention time (HRT) and sludge retention time (SRT). Due to the absence of secondary clarifiers, the overall size of treatment plant can be greatly reduced (Stephenson et al, 2000).

Further, Scott and Smith (1997) reported a result that the membrane of 0.2 mm pore size provided markedly superior aeration to a traditional sparger, and we consider if ceramic membrane of 15mm pore size can provide also markedly aeration and also discuss its filtration property.

Materials and methods

Bioreactor with dual functional ceramic membrane is shown in Figure 1. Its working volume was 5 – 8 L, which could be determined by level meter according to the hydraulic retention time, and the wastewater was automatically pumped into bioreactor according to the level meter during the test. Two groups of ceramic membranes were installed on the bottom of the bioreactor, and aeration and filtration could be alternated automatically in certain interval according to the demanded.

Figure 1. Schematic of bioreactor with dual functional ceramic membrane

The ceramic membranes were formed like U tube as shown in Figure 2, which was designed to install and uninstall conveniently and easily. The membranes had pore size of about 15 mm and surface area of 55 cm2 per membrane. There were two membranes per group during operation. Effluent was pumped by measuring pump with very low pressure through the ceramic membranes.

Figure 2. Ceramic membrane like U tube

To determine if the ceramic membrane could be competent for aerator, the ceramic membranes were inspected for its oxygen transfer coefficients compared with gritstone sparger. Ceramic membranes were also respectively used for tap water and wastewater filtration to inspect its flux change under the condition of 20°C at first. The simulation wastewater was used in the experiments, which included glucose, ammonium chloride, dipotassium hydrogen phosphate and some yeast extract in term of certain rate to get the simulation wastewater with COD: 340~1077 mg/L, NH3-N: 11~38 mg/L, turbidity: 34~98 NTU and pH was adjusted between 6.2~7.5. Analytical items included COD, NH3-N, turbidity and sludge concentration etc. Fouling membranes were washed with several washing agents including inorganic acid and alkali and oxidizing agent with 1% concentration, and the methods were that foul ceramic membranes were immerged in the agents for 2~10 hours, then washed by tap water. Ultrasonic and absorbent cotton were also used for membrane washing in order to compare with the washing methods mentioned above.

Results and discussion

Ceramic membrane compared with griststone sparger on oxygen transfer coefficients

The ceramic membrane was inspected for its oxygen transfer coefficients compared with gritstone sparger as it was usually used for aerator. The bioreactor was filled tap water of 8 L, and oxygen was removed to zero by sodium sulfite at first, then the water was successively aerated through ceramic membrane and gritstone sparger, and dissolution oxygen concentration in tap water increased gradually, here the aeration rate was 0.3m3/h. The oxygen transfer coefficients can be described as below (Schügerl K. 1985):

Here C —— Dissolution oxygen concentration at t (mg×L-1);

t —— Time (h);

Cs—— Saturated concentration of dissolution oxygen under experimental temperature and pressure of (mg×L-1);

KLa——Oxygen transfer coefficient (h-1)

The logarithm of dissolution oxygen concentration was drawn vs time as shown in figure 3. Ceramic membrane expressed higher transfer coefficient than griststone sparger according to figure 3, which indicated that ceramic membrane could be competent for aerator in wastewater treatment. The KLa was respectively 0.2315 h-1 and 0.0991 h-1 for ceramic membrane and griststone sparger according to the regressions.

Figure 3. Ceramic membrane compared with griststone sparger on oxygen transfer coefficients

Flux change

When tap water filtrated through ceramic membrane, the flux maintained about 0.7 m3/m2×h, but the flux declined sharply without switch for wastewater filtration under sludge concentration of 4000mg/L. The flux change situations are shown in figure 4.

Figure 4. Flux change for tap water and wastewater

The relation of switch interval of aeration / filtration and the flux of ceramic membrane

For ceramic membrane, the flux of would decline with filtration of wastewater, but it could be recovered partly by switching from filtration to aeration, so switch period would be an important parameter for its application in wastewater treatment. The operation was done under sludge concentration of 4000mg/L with two groups of new ceramic membrane. The recover situations are shown in figure 5, 6 and 7, which were respectively corresponding to switch at 10, 20 and 30 minutes intervals.

When switch interval was set in 10 minutes, the flux would not decline below 0.1 m3/m2×h and recover more than 95%, but the flux would decline below 0.1 m3/m2×h in 20 and 30 minutes intervals according to the experimental results. So the switch interval was set in 10 minutes in latter test, which would help to avoid irreversible foul on the ceramic membrane.

Figure 5. Flux recover of ceramic membrane by switch at 10 minutes intervals |

Figure 6. Flux recover of ceramic membrane by switch at 20 minutes intervals |

Figure 7. Flux recover of ceramic membrane by switch at 30 minutes intervals

Wastewater treatment

Turbidity change

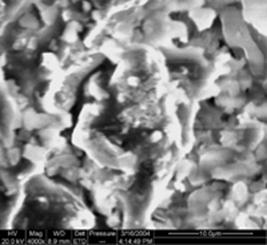

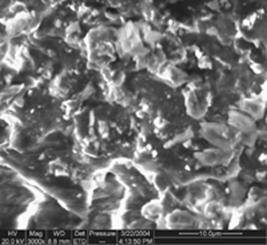

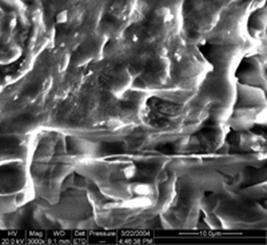

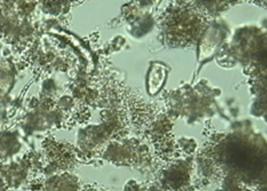

Treated wastewater was filtrated by measuring pump through ceramic membrane for 100 days and its turbidity change is shown in figure 8. Suspend granules removal ratio was more than 99 percent and the effluent turbidity was less than 1 NTU under the condition of 10 minutes switch interval and sludge concentration of 4000 mg/L, which was equaled to the natural gravity sedimentation of 12 to 36 hours. The treated wastewater penetrated through sludge bed formed on ceramic membrane with pore size of 15 mm, which could be observed and proved from figure 9, 10 and 11. Figure 9 is outer surface of original ceramic membrane, and figure 10 shows the sludge bed formed on the outer surface of ceramic membrane and its pore size is obviously less than that of original ceramic membrane. Figure 11 is inner surface of foul ceramic membrane and its pore size is near to original ceramic membrane, but a little sludge could be found, which would be maybe main factor to result in irreversible foul.

Figure 8. Turbidity change during the operation

Figure 9. Outer surface of original membrane |

Figure 10. Outer surface of foul membrane |

Figure 11. Inner surface of foul membrane

COD removal

When the bioreactor was used for wastewater treatment for 100 days, and influent COD was increased gradually, the average COD removal ratio was about 90% under activated sludge concentration of 4000~5000 mg/L, hydraulic retention time about 8 hours and organic loading of 1.2~1.5 kgCOD/m3×d, especially in latter operation, the COD removal ratio was more than 90 % with influent COD increased. Figure 12 shows total COD removal situation, here the COD removal ratio was respectively about 73.8% by activated sludge in bioreactor and 16.3% by ceramic membrane filtration in corresponding to total removal ratio of 91.1% according to the test as shown in figure 13, which indicated that ceramic membrane also played a certain important role in total COD removal.

Figure 12. COD removal situation during the test

Figure 13. Relation between membrane removal ratio and sludge removal ratio

Figure 14 shows that some Protozoa and Metozoa appeared in activated sludge, such as Vorticella and Aeolosma hemprichii, which is usually an indicator to express better situation of biological treatment of wastewater, i.e. implies higher COD removal ratio (Zhou and Gao, 2000).

Figure 14. Protozoa and Metozoa appeared in activated sludge in bioreactor during the test

NH3-N removal

Figure 15 shows that N3H-N removal ratio was more than 98 percent accompanied with higher COD removal during the operation of 100 days, as biomass residence time is independent of hydraulic retention time, which is propitious to nitrifying bacteria and denitrifying bacteria. The influent concentration of N3H-N increased gradually from 8 mg/L to 50 mg/L during the operation, but effluent concentration of N3H-N was less than 1 mg/L all the time.

Figure 15. NH3-N removal

Membrane foul and recover

The membrane fouling could be palliated because the membrane could be switched from filtration to aeration, but the irreversible fouling would occur after all, because sludge bed formed on the surface of ceramic membranes and slow liquid velocity through the membrane surface, usually higher liquid velocity passing surface could avoid sludge stay on the surface effectively, in addition, microorganism would grow within the micro-pore of ceramic membrane to result in irreversible foul. The ceramic membranes were uninstalled for cleaned in order to recover its flux after they were used for two weeks during the test, as membrane flux declined. Several washing agents including inorganic acid and alkali and oxidizing agent with 1% concentration were used for washing ceramic membrane and the methods were that foul ceramic membranes were immerged in the agents for 2~10 hours. Besides these washing agents, the foul ceramic membranes were also immerged in water and washed by ultrasonic methods for 5~10 minutes. For compared, the surface of foul ceramic membrane was also cleaned by absorbent cotton. The sludge covered on the surface of ceramic membrane is maybe main factor to the foul, because the flux of cleaned membrane by absorbent cotton is near to that by ultrasonic and NaClO according to figure 16. In addition, the experimental results indicated that NaClO was better washing agent than other agents to recover due to its strong oxidization, and some microorganism and organic matter within micro-pore of ceramic membrane could be oxidized by NaClO and H2O2, which is propitious to flux recover.

Figure 16. Recover situation of ceramic membrane.

Conclusion

Ceramic membrane is better than griststone sparger on oxygen transfer coefficient when it was used for aerator, and wastewater penetrated through sludge bed formed on ceramic membrane when it was used for filter. The COD was removed more than 85% and membrane removal played important role in the total COD removal. NH3-N removal ratio is more than 98% because biomass residence time is independent of hydraulic retention time, which is propitious to nitrifying bacteria and denitrifying bacteria. The flux could be easily prevented or avoided by switch for reversible foul, and flux could be recovered by NaClO for irreversible foul.

Acknowledgements

The authors acknowledge the financial support of Jiangxi Bureau of Environmental Protection.

Reference

Beaubien A., Baty M., Jeannot F., Francoeur E. and Manem, J. (1996), Design and operation of anaerobic membrane bioreactor: development of filtration testing strategy, J. Membr. Sci. 109 173-184.

Chiemchaisri C., Yamamoto K. and Vigneswaran S. (1994). Household membrane bioreactor in domestic wastewater treatment, Water Sci. and Technol. 27. 171-177.

Owen G., Bandi M., Howell J.A. and Churchouse S.J. (1995) Economic assessment of membrane processes for water and wastewater treatment, J. Membr. Sci. 102, 77-91.

Scott J.A. and Smith K.L., (1997). A bioreactor coupled to a membrane to provide aeration and filtration in ice-cream factory wastewater remediation. Wat. Res., 31, 69-74.

Schügerl K. (1985). Bioreaction Engineering, Translated from the German by Valerie Cottrell in 1987, John Wiley & Sons, Chichester.

Stephenson T., Judd S., Jefferson B. and Brindle K. (2000). Membrane Bioreactors for Wastewater Treatment, IWA Publishing, London, UK.

Trouve E., Urbain V. and Manem J. (1994). Treatment of municipal wastewater by a membrane bioreactor: results of a semi-industrial pilot study, Water Sci. and Technol. 30, 151-157.

Zhou Q. and Gao T. (2000). Microbiology on environmental engineering, Higher Education Press, Beijing, P. R. China, (in Chinese).

相关推荐

- Preparation of High Concentration Polyaluminum Chloride with High Alc Content by Membrane Distillation

- Nitrifying Population Optimization in Municipal Saline Wastewater Treatment

- Separation of Sulfur/Gasoline Mixture with Polydimethylsiloxane/Polyetherimide Composite Membranes by Pervaporation

- Characterization of the start-up period of single-step autotrophic nitrogen removal in a sequencing batch reactor

- RES EARCH ON MEMBRANE B IOREACTOR TREATING DOMES TIC WAS TEWATER AND RELATED MECHAN ISMS

- Micro-Polluted Surface Water Treatment by PAC-MBR Process

论文搜索

月热点论文

论文投稿

很多时候您的文章总是无缘变成铅字。研究做到关键时,试验有了起色时,是不是想和同行探讨一下,工作中有了心得,您是不是很想与人分享,那么不要只是默默工作了,写下来吧!投稿时,请以附件形式发至 paper@h2o-china.com ,请注明论文投稿。一旦采用,我们会为您增加100枚金币。